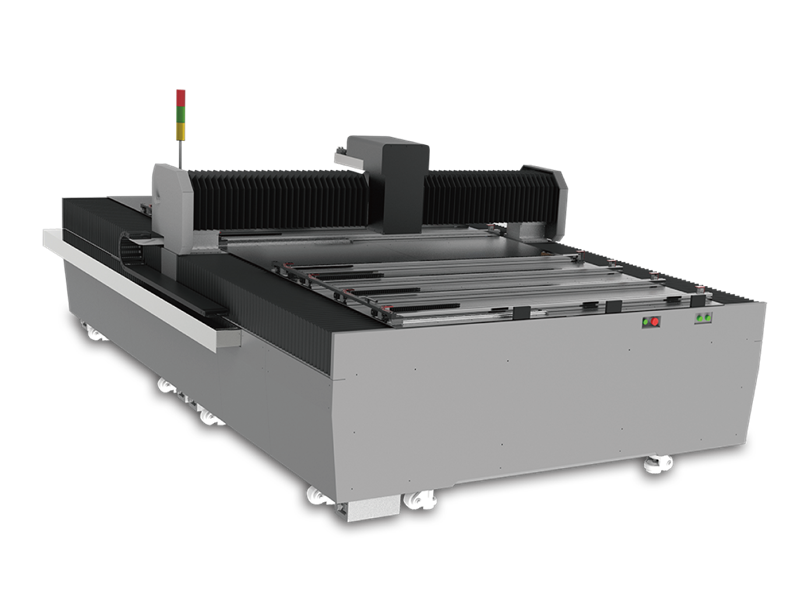

DIS-300

CTS Application advantages

resolving power1270dpi/2540dpi,Screening 133 line

High capacity:

Exposure of 1 square meter screen plate takes only 3 minutes; Accurate exposure alignment saves printing preparation time and reduces labor

Reduce costs:

Since there is no need for film, it can prevent quality problems caused by film wear and unstable expansion and contraction. At the same time, the film price is high and a lot of costs are saved;

increase of efficiency:

Accurate exposure alignment saves printing preparation time and reduces labor

Application industry:

Toys, printing, flower paper, hot stamping, packaging, label, decoration, textile, PCB, film switch,Mobile phone cover glass screen printing, 3C industry screen printing, automotive glass, photovoltaic, etc

Advanced CTS solution manufacturer

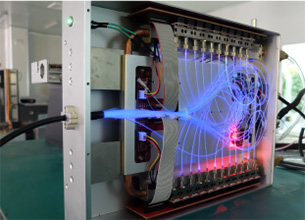

CTS It adopts industry-leading purple laser technology, DMD core components of TI company of the United States, high-power 405nm laser module, high-precision linear motor motion system and stable water cooling system. It can directly expose the screen surface with high precision, saving the film process. Bring high resolution, high efficiency and low cost products to customers. This latest digital exposure system (CTS) will become a new standard in the industry

Fully compatible with traditional processes

CTS laser plate making machine directly reads the data file and can read format 1_ Bit, converted into images, exposed and imaged by laser head projection. The front and rear processes are fully compatible with traditional processes. It is suitable for screen printing industries such as printing, fancy paper, packaging, PCB, label and label, automobile glass, household appliance glass, electronic glass, decoration and so on.

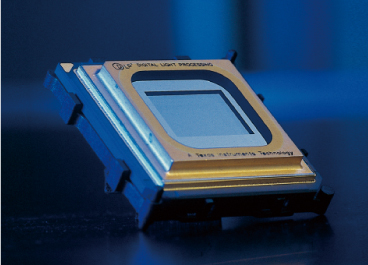

Digital imaging technology

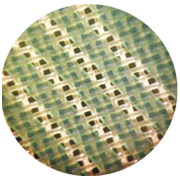

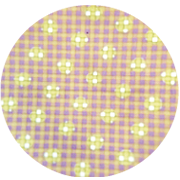

Ti's pattern generator digital micromirror device (DMD) chip is used to generate digital images. DMD is composed of 800000 or 2 million micromirrors, which can ensure clear and sharp square dots within the light spot range of DMD. This latest digital exposure system has become a new standard in the industry.

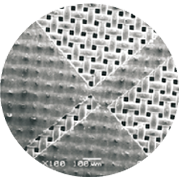

high resolution

The optical resolution of 1270 DPI can easily be added to the accuracy of 133 lines to achieve the high fidelity effect of dots. The optical resolution of 2540 DPI can not only express the high-definition curve, but also perfectly express the FM dot. Dot printing can realize 133 line four-color screen printing, and the density gradient of more than 3% is smooth.

2540dpi

Line width 50um

5% Network

Four color net picture

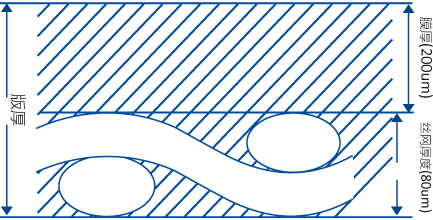

Excellent laser penetration

Excellent laser penetration, providing three laser powers of 15 W, 20 W and 25 W, which can penetrate solvent 120 μ M and aqueous thick film plate 220 μ m. Suitable for special screen printing, such as carbon oil, water film and so on.

| Specification / model |

DIS-300

|

|---|---|

| Scope of application | Toys, printing, labels, textiles |

| Maximum mesh frame size(mm) | 800*900 |

| Minimum mesh frame size(mm) | 300×400 |

| Maximum exposure range(mm) | 700x800 |

| Net frame thickness | 25-40mm(Customizable) |

| Imaging system technology |

DMD

DLP

technology

|

| Photosensitive film thickness | Solvent based photosensitive adhesive: 3μm-120μm,Water sexy light glue: 3μm-220μm |

| time of exposure | 3μm-50μm;120-240s/m²;350 mesh yellow net, (SBQ photosensitive emulsion) |

| Image analysis |

1270DPI

|

| screen frequency | 100LPI(MAX) |

| Focusing mode | Dynamic instant focus |

| file format | Gerber74X/1_bit tiff |

| Laser type | UVLDLaser |

| Laser energy |

15W/20W/25W(Optional)

|

| Equipment size (mm) | 1400x1500x1600 |

| Net weight of equipment | 1.2T |

| work environment | Yellow light room; Dust free grade: 10000; Temperature: 22 ± 2 ° C; Relative humidity: 40-55% (no condensation) |

| power | Power Supply: Single phase 220V, 50 / 60Hz, 4kw; gas:1L/min |

*Specifications are subject to change without notice